Blog

How to make the sludge dewatering process more efficient and better?

By choosing the right chemicals, setting up the machine and proper dosing, you can achieve the desired cost reduction.

What is important to follow concerning sludge dewatering process at wastewater treatment plants? How do you know if you are managing the sludge in the right way? These topics will be also discussed in this article, which describes how to set up the process, dosing and handling of the sludge so that the sludge dewatering line works as efficiently as possible in terms of both efficiency and finances.

Before I begin, I would also like to emphasize that the sludge in municipal wastewater treatment plants will also be mentioned in the article, and I will also come to the specifics relating to sludge produced by industrial wastewater treatment plants.

You shall approach the flocculant selection seriously

Choosing an adequate flocculant requires time and is not recommended to be underestimated.

Therefore, I recommend that you approach this dilemma by inviting an expert who understands how flocculants work in the details to make the process run as efficiently as possible.

First of all, do not let yourself be assured that the flocculant can be easily selected at a distance. It is true that sludge (mainly from the communal sphere) is similar and therefore its type and charge can be estimated (anionic / catioactive, powder / emulsion). However, it would be right to subject your sludge to a flocculation test with different types of this product.

Once you've decided for the tests, you should definitely observe several properties of flocculant sludge reactions, first of all whether flakes are formed.

Their formation and size do not always indicate a sufficient compactness of the flakes, so try to verify their strength, for example at least with a simple mixer.

If you don´t test their strength, it is possible that they will break down during dewatering and the required sludge dryness and purity of the fugate (the liquid phase resulting from the dewatering process) will not be achieved.

I have had such an experience from my recent business trip when we had a mix of activated sludge from biology and sludge from flotation unit in a food factory. In the laboratory, our flocculant seemed to react very well - creating good flakes.

However, in the centrifuge, at the best will, we could not achieve a dry matter content of more than 15%.

Make a financial evaluation of the dewatering process

After all, it is important to make a financial statement, not least, to find out if better but perhaps more expensive flocculant really pays off.

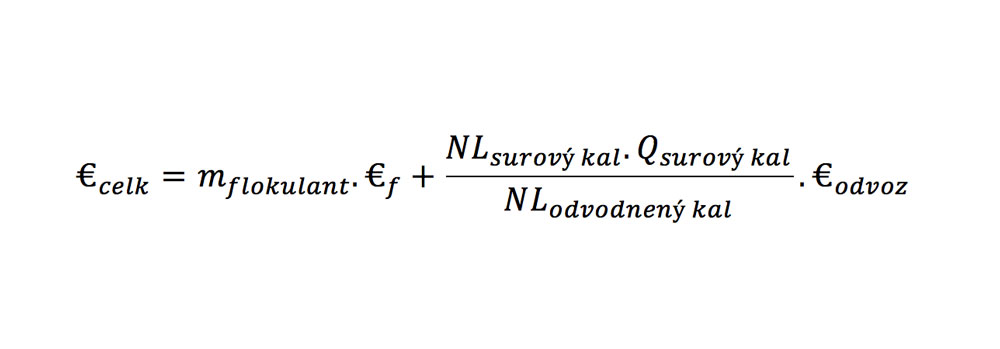

In this case, it is necessary to take into account the costs of the flocculant, the cost of getting rid of drained sludge and the difference in the amount of dry matter of the sludge of one and the other flocculant (see the following equation).

€total – total cost for flocculant, transport of drained sludge and its proper disposal per day (€.d-1)

mflocculant – needed (spent) amount of flocculant per day (kg.d-1)

€f – price for 1 kilogram of flocculant (€.kg-1)

NLraw sludge – concentration of undissolved substances in raw sludge before dewatering (kg.m-3)

Qraw sludge – amount of processed raw sludge on the sludge dewatering line per day (m3.d-1)

Dried sludge – concentration of undissolved substances in drained sludge (or sludge dry matter) (kg.m-3)

€disposal – finances needed for the removal of 1 cubic meter of dewatered sludge (€.m-3)

Save when dosing

Another area where the sludge dewatering line could save some money is the flocculant dosing in the dewatering process. The dose optimization area can also be done in a so-called "DIY" way on the wastewater treatment plant. You only need enough time.

1.

You set the constant sludge flow rate to the drainage line (for example, to the centrifuge). It is necessary to work with its constant composition and concentration because these parameters are important factors that affect the reactions with the flocculant.

2.

Gradual decreasing or increasing the dose of flocculant at a constant concentration will cause an increase or decrease in dry matter of the sludge.

3.

Always after the change you have to wait a while for the state to settle.

4.

Subsequently, samples can be taken and visual and laboratory findings made. In most cases, what we want to achieve is the highest dry matter of the sludge (high concentration of insoluble matter) and the lowest concentration of insoluble matter in the fugue (the liquid phase resulting from dewatering).

5.

Then, an optimal flocculant dose can be set, but let me repeat - for sludge with the same composition. The optimal dose can also be determined for higher or lower sludge flow rates.

Landfilling, composting or sludge incineration?

If we look at these ways of sludge management only from a transport perspective, it is important to have it as little volume as possible - to get rid of excess moisture in order to avoid unnecessary weight and volume to be carried and transported. To achieve higher solids level, it is possible to invest in, for example, into so called sludge fields.

The ideal situation is when the fields can also be covered. Their advantage is that solar energy utilizes energy from the sun, which evaporates the water from the sludge and saves us the cost of heat supply. The roofing bonus is that the rain does not re-moisten it in the event of rain.

It is also interesting to consider the idea that in the future it might be necessary to process the sludge from the WWTP in other ways we are currently used to. Some sludges, for example, are burned today because of their composition (dangerous substances and such).

The extension of the sludge spectrum that will be condemned for burning may concern sludge from larger WWTPs (mainly for the recovery of phosphorus) or wastewater treatment plants in which substances such as drugs, heavy metals or petroleum can be absorbed into the sludge.

Therefore, it is advisable to think carefully over the solutions that provide the lowest weight and the highest dry matter, which will contribute, for example, to more efficient combustion and more efficient transport.

Other ways to optimize the dewatering process

If it is necessary to use a large amount of flocculant, but the pump capacity is at its maximum, it is possible to increase the concentration of the solution.

By simply adding some more flocculant powder to the same volume of water at the point where the solution is made. Such a setting has its limits defined by the solubility of the flocculant. If the dose is exceeded, unabsorbed clots will form in the volume.

Important issue that affects the dewatering process is the machine settings by itself. Make sure the first and the simplest step is reading its manual and trying to understand the content. You can then try to set up the ideal machine settings individually or with expert help.

It may also happen that the selected technology is really inappropriate for your sludge. Its composition is closely related to the processes going on in production. Therefore, it will never be useless to make a pre-purchase survey of already-existing plants with similar production and similar products. The quality of wastewater and sludge should be very similar.

Summary at the conclusion

In the text, we have touched areas like cost saving of wastewater dewatering line of the wastewater treatment plant. Savings can be related to proper flocculant selection for your sludge or exact dosage setting to ensure efficient handling of the process. We also covered the issue of achieving the lowest possible dry matter of the sludge and to possibility to incinerate the sludge.

I strongly believe that my article was helpful. And if not even directly in the WWTP, at least as a short excursion into the topic of the sludge dewatering process.