Blog

How to deal with highly polluted wastewater in starch industry

Read how Hydrotech engineers have designed the process of anaerobic purification of starch wastewater.

Usage of wheat and starch from it is really wide. Heaps of wheat, large quantities of starch, starch in beverages, starch in meals, starch in pet food, starch in paper, starch in drugs ... Like most manufacturers, they also need water for water-related processes. I recently returned from the business trip where I spent a fair amount of time trying to help to treat the polluted water produced by factory.

Anaerobic purification of starch wastewater

Our company, Hydrotech, has been putting into operation their anaerobic-aerobic wastewater treatment plant.

The design of our technology has been based on the following information.

This is a food industry, a fairly simple biodegradable substrate present in wastewater and the concentration of wastewater pollution is relatively high.

That is why we have decided to carry out a treatment based on a high-volume anaerobic system with internal recirculation – so called IC reactor.

As the final stage of purification to achieve the required limits, an aerobic degree was designed, which is a classic biological purification by aerobic bacteria in aerated tanks.

Problem no. 1 – quality of anaerobic sludge

Over a period of three months we have been facing various problems that was brought by plant start-up. One of the main problems was anaerobic sludge with anaerobic bacteria.

As the start-up of the reactor was postponed for several months because of the unevenness in the inflow, the sludge was stored in the reactor for about a half of a year.

The theory says that this type of bacteria, without any major problems, must retain its functionality for a year or two when properly stored.

The biggest disadvantage may be that bacteria will need a longer lead-in phase for adaptation.

Although this theory asserts, we have been unable to significantly increase the activity of the organisms under these circumstances and, in the middle of the run, we have decided to aquire some new anaerobic sludge.

I do not want to claim here that the textbooks are lying, and you can not believe them. I really can not say that.

Probable cause of poor cleaning

Our team of process engineers agreed that the sludge was likely to settle on the bottom of the tank in such a way that it created a compact layer that could not be mixed with water.

For this reason only some passageways have been formed in the layer and the non-specified part has not been mixed and has not come into contact with the wastewater.

The answer to the question why this is the case is that it is probably related to the quality of aquired sludge, which was too heavy, meaning that it had a lot of inorganic content (40-45%).

The new sludge was working completely differently. Within one week, we processed more than half of the wastewater.

After two weeks, we were able to process the entire volume of wastewater, except for cases where very concentrated watsewater came in larger volumes.

Problem no. 2 – excessive leaching of anaerobic sludge

At this stage, however, we started to encounter another problem.

It was the leaching of sludge from the reactor in the form of suspended fine particles.

It's not unusual during start-up. Even about 10 percent loss is expected which is related to the damage of sludge due to transport and pumping.

But when sludge leaching did not appear to stop, we began to look for other reasons for suspicious behavior of the system.

In the first phase, we started to feed-in ferric chloride in relatively small amounts, which we have increased several times over the persisting problems period.

Iron should cause the sludge to be loaded with inorganic mass, thereby mitigating its discharge.

It worked somewhat to some extent, but not in what we expected and needed.

Why are micronutrients needed?

It is most likely that it looks like the problem is caused by wastewater poor on minerals, mainly because of water treatment in the factory.

In production, this is basically a normal process when you want to achieve some desired product quality, which is influenced even by low concentrations of minerals.

The second disadvantage in this particular factory is the fact that even concentrated mineral streams from reverse osmosis units enter another company sewer.

It does not enter the wastewater treatment plant, but it flows around it, so it seems to lack the so-called micronutrients in it.

These substances serve as nutrients for any organism. They are nutrition for healthy cell growth. In this case, some elements and compounds form the so-called granulation cores around which bacteria may begin to grow.

If the system was running for a long time without the addition of nutrients (micronutrients), we could expect total collapse of the whole system.

The importance of pre-treatment of wastewater before the IC reactor

We also paid great attention to pre-treatment of waste water. It is not good for the process if high concentrations of undissolved substances are entering it. Flotation is used as the primary purification step, fulfilling its role without major problems.

After some time, when we observed that the concentrations of undissolved substances are low for the long period of time, we stopped dosing one of the chemicals.

The flocculant should provide better bonding of smaller undissolved particles to make separation more efficient. The danger is, however, if the flocculant has no reaction and does not leave in the form of larger clusters of undissolved substances separated in the flotation.

If it passes through the system up to the reactor, it can cause flocculants to envelop the granules, join them into larger units, and then their discharge. Therefore, we moved to a safer side and stopped the flocculant completely.

Benefit of anaerobic treatment – biogas

A big advantage of anaerobic system is the production of biogas which consists of 60 to 90% of energy-rich methane.

Unfortunately, at this factory they still don't know what to do with the biogas, so they just burn it. It's a shame, because this product can be used as a source of energy for burning in the boiler or can be burned in the so-called cogeneration units to produce green electricity and heat.

Perhaps after the process has stabilized, this issue will also be solved effectively.

Other problems

Well, if the start-up difficulties were to remain this way, it would be too simple. I could continue to mention problems in wastewater quality, freezing of solutions at temperatures well below zero, freezing of pressure gauges, as well as noise, dosing, foaming of the aerobic step and many others.

Use and presence of starch in products

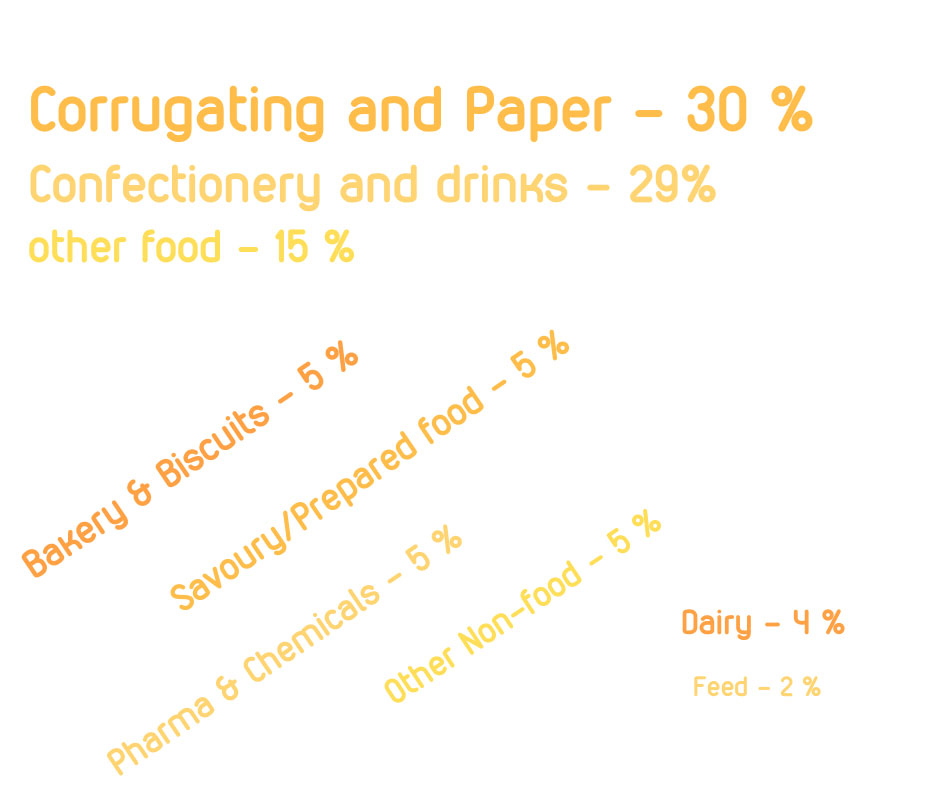

Although this factory is located outside the European Union, we can take into account the figures from The European Starch Industry (2017), according to which 29% of starch is used as an ingredient in confectionery and soft drinks, 30% in the paper industry, another 29% in others 5% in the chemical and medical industries and 5% belong to the non-food sector.

So we can see that the need for the starch industry is really large.

That is also one of the reasons why I am pleased to see that the start-up of wastewater treatment plant, even though not always smooth, was almost completely accomplished. In this blog article I tried to draw attention especially to the problems of anaerobic system related to sludge granulation. I hope that the process will only need to be monitored and controlled.

More articles

Waste treatment tests from dairy industry in anaerobic way

Treatment tests of concentrated waste material from dairy factory are currently being run in our laboratory. Process advantages are as follow: biogas...

The market for wastewater treatment technologies is set to double by 2020

The wastewater treatment sector is considered to be the fastest growing global business.