Leopoldov

Industrial and sewage / Biofuels

Our industrial sewage treatment plants are supplied to various industries. Specifically for food, automotive, textile, paper / pulp and cellulose, chemical as well as pharmaceutical industry. In addition, we provide sewage treatment plants for the processing of ores and animal waste (rendering plants).

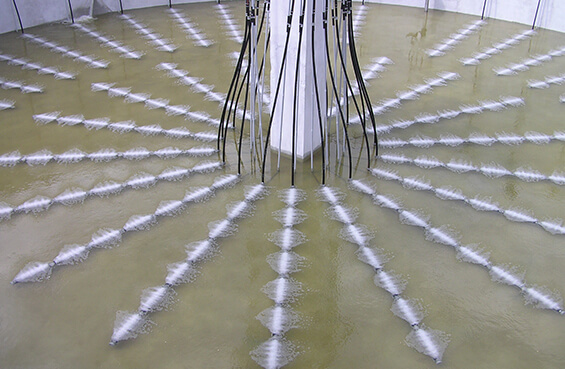

In order to purify concentrated industrial waste water, we successfully apply a solution for anaerobic purification where we also use technology producing significant quantities of biogas. Thanks to this, your WWTP can produce electric or thermal energy. In addition, we can help you with the efficient cleaning of wastewater with high nitrogen, phosphorus or sulfur content.

Wastewater treatment plant for the bakery is in the execution project stage. Capacity of WWTP is the same as for a city with approximately 22,000 inhabitants. Technology used within the plant is divided into 2 sections. The first one is a mechanical part involving rotary sieve, accumulation tank and flotation unit. The main function is to remove bigger particles from wastewater, equalize water quality and remove part of pollution. The second part of the WWTP is a biological stage, where water is treated up to the required parameters with help of activated sludge (microorganisms).

A model example of the design and gradual implementation of pre-treatment of industrial wastewater is a project for treatment of wastewater from textile industry. It is a production of textiles used mainly for hot air balloons. Most of the pollution comes from the dyeing line. The beginning of this project consisted of pilot tests of wastewater treatment using flotation, which lasted roughly 2 months. During this period the ability to remove pollution with such technology was demonstrated, so the customer ordered a proven solution.

One of our current customers is interesting because they produce ammunition. No industrial wastewater is produced directly in the production, but some volume is produced by employees and productions located near the factory. The project design involved effective use of existing tanks and transformation of biofilm technology into a conventional system of aerated and mixed tanks with suspended activated sludge.